Batteries

Dedicated Test Centre for Battery Testing and Homologation

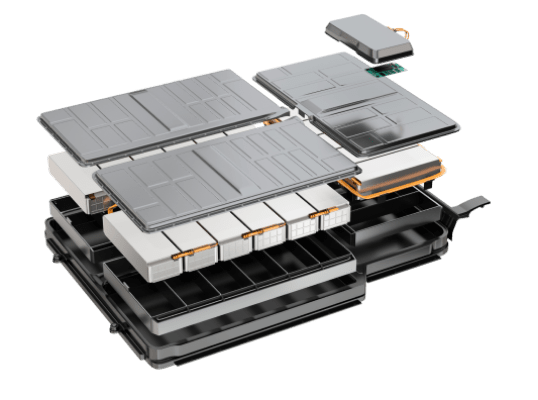

Lithium Batteries are one of the most differential components in battery electric, hybrid electric and fuel cell electric vehicles (EV, HEV/PHEV and FCEV). Due to safety hazards, batteries must comply with strict test standards to ensure they will continue to resist all the environmental factors they will face throughout their life cycles (shipping, operations, crashes, etc.).

While some of these tests are performed at cell or module level (e.g. altitude), others must be carried out at battery pack level, which requires specialist test equipment in terms of size and safety measures. Our dedicated battery test center in the UK has 1.5 MW installed power and boasts a wide range of specialist facilities for battery testing and type approval, including a safe battery storage facility.

A UNIQUE SHAKER FOR BATTERY PACKS

Our test system for full-vehicle battery packs is the only one of its kind in the UK and one of only a few in Europe. It contains an immense shaker that operates from inside a large climatic chamber equipped with an emergency detection system for battery failures

- 200 kN for random and sine vibration testing

- 400 kN for shock testing

- Coupling with a large climatic chamber

- For batteries packs up to 2.8 m x 2.8 m

COMPREHENSIVE BATTERY TESTING CAPABILITIES

Combining our UK lab and global Applus+ facilities, we have the equipment and expertise to conduct a wide array of battery tests for both modules and packs.

Environmental, Fire & Mechanical testing

- Thermal Shock (Dual climatic chamber)

- Temperature / Humidity testing (from -70ºC to 180ºC)

- Corrosion / Salt Spray

- Altitude

- Cycling

- Fire

- Mechanical Shock

- Mechanical Integrity

- Battery Abuse

EMC testing

Our semi-anechoic chambers for full-battery and integrated Battery Management Systems (BMS) testing offer the perfect solution for EMC testing.

- 10 m x 4 m x 3 m (minimum)

- 3 t floor load capability

- Battery packs up to 2.8 m x 2.8 m

EV BATTERY STANDARDS AND REGULATIONS

Applus+ 3C Test provides a complete testing and homologation service for batteries following the main testing standards and regulations. We work in collaboration with Applus+ companies to offer a one-stop-shop service.

UN 38.3

Battery Transportation

T1 – Altitude simulation

T2 – Thermal test

T3 – Vibration

T4 – Shock

T5 – External Short Circuit

T6 – Impact/Crush

T7 – Overcharge

T8 – Forced Discharge

UNECE R100 (& R136)

Battery Safety Homologation

9A – Vibration tests

9B – Thermal shock and cycling tests

9C – Mechanical shock

9D – Mechanical integrity

9E – Fire resistance

9F – External short circuit protection

9G – Overcharge protection

9H – Over-discharge protection

9I – Over-temperature protection

9J – Over-current protection

UNECE R10

EMC Homologation (BMS)

Radiated Emissions

Radiated Immunity

Transient Emissions

Transient immunity

OEM STANDARDS

Environmental Testing

Based on:

ISO 19453-6:2020